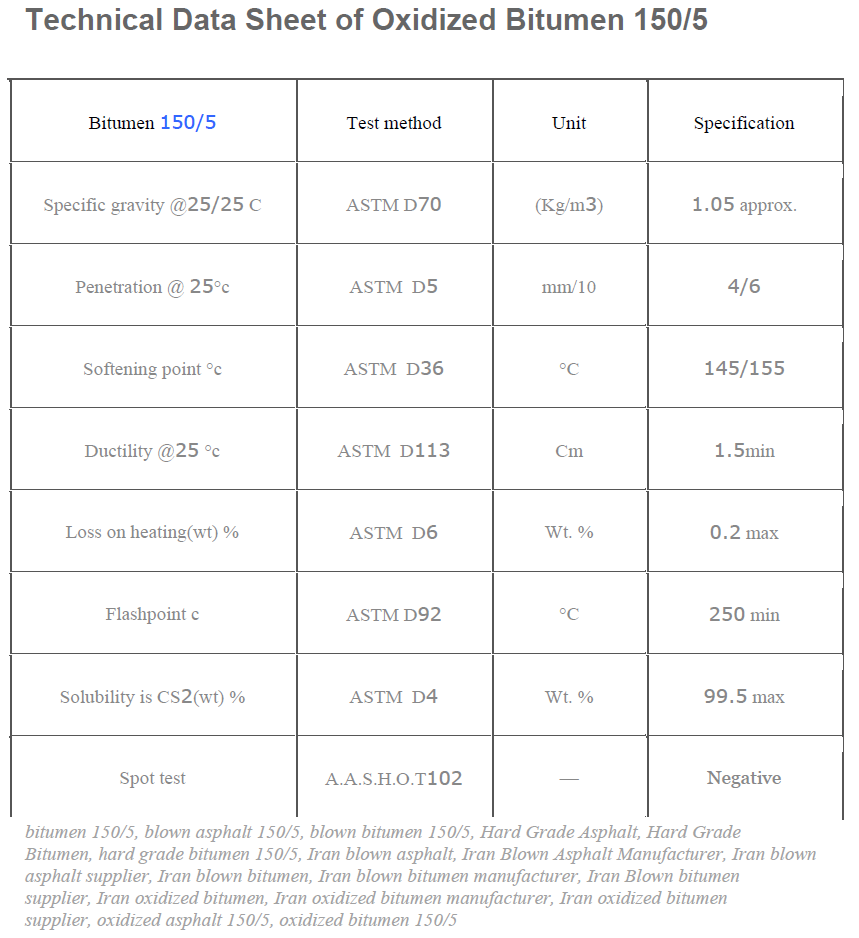

Oxidized Bitumen 150/5 is produced by either the Continuous or Staggered Blowing Process. Heated Penetration Grade Bitumen is blown with air in a controlled environment, which regulates the oil content in the bitumen during oxidation. The different grades produced for various applications are designated by two numbers indicating the midpoints of their softening point and penetration ranges.

Blown Asphalt 150/5 is based on petroleum bitumen produced by blowing Bitumen 60/70 with hot air. Bitumen 150/5 refers to a softening point of 150°C and a penetration value of 15 desi-millimeters, produced in conformity with ASTM standards. This type of bitumen is hard and brittle. Heating of this hard oxidized bitumen should be conducted using hot oil circulated inside an isolated jacket. RAHA Bitumen 150/5 is available in various grades as required.

RAHA Bitumen Co. also manufactures other grades of Oxidized Bitumen tailored to specific client requirements. Oxidized Bitumen offers several advantages: it is completely water resistant, highly flexible, durable, and chemically stable. These characteristics make it a highly desirable compound for numerous industrial applications.

Bitumen

virgin_oilD6

Uses of Blown Bitumen 150/5

Oxidized Bitumen 150/5 is widely used in:

- Anti-slip layer compounds in the piling industry

- Roofing felts

- Sound dampening felts

- Under-carriage sealants in the automobile industry

- Electric cable joint protection

- Joint filling and sealing compounds

It is also used as a raw material in:

- Bitumen coats

- Roofing

- Insulation

- Isolation bitumen membrane sheets

Additional applications include:

- Chemical and fuel industries

- Paints, lacquers, varnishes

- Paper, pulp, and board industries

- Textile processing

- Road construction (pavement, crack sealing, repair)

- Civil works

- Building sealing and insulation

- Adhesives and construction additives

- Dust-binding and coatings

- Insulating and impregnating agents

- Rubber and plastic manufacturing

Bitumen 150/5 is also used for:

- Paving and roofing

- Asphalt-based paints for corrosion protection

- Inlining public works structures

- Adhesives in electrical laminates

- Base for synthetic turf

- Hydraulic applications

- Paint manufacturing

Technical Advantages of Blown Bitumen 150/5

- Durability

- Flexibility

- Water Resistance

- Chemical Stability

Compared to paving grade bitumen:

- Reduced temperature susceptibility

- More solid nature at ambient temperatures

- High penetration index

Storage & Handling

Heating of packaged bitumen is a critical phase in most applications. Typically, the material is heated and melted in on-site boilers. Proper control during heating is essential for both health and safety and maintaining product quality.

- Maximum safe handling temperature: 230°C (must not be exceeded)

- Bitumen is a poor conductor of heat; heating must be carefully controlled

- Break the bitumen into smaller pieces before heating to expose more surface area and ensure even melting

- Avoid localized overheating at the base and sides of boilers, which can alter bitumen characteristics and cause thermal cracking

- Never reheat solidified bitumen from cold; this can lead to poor heat transfer, localized overheating, and pressurized vapor pockets

- Ensure temperature monitoring devices are correctly placed; readings may vary drastically depending on the location within the bitumen

Health & Safety

Workers must wear protective masks, gloves, and goggles during application. Asphalt residue can be removed from tools and equipment using kerosene or gasoline. Overheating of Oxidized Bitumen 150/5 must be avoided to ensure safety.

Packing of Oxidized Bitumen 150/5

RAHA GROUP manufactures Oxidized Bitumen 150/5 in various packing options:

- 20 & 50 kg Kraft Paper Bags / Poly Amide Bags

- 25 kg Carton Boxes

- 150, 180 & 200 kg Steel Drums