Blown Bitumen 75/25, also known as Oxidized Bitumen or Blown Asphalt, is produced by blowing hot air into penetration grade bitumen. This process makes the bitumen more rubbery than its original form and results in a harder material. This form of bitumen recovers weight loss under heating. Due to its low thermal sensitivity, the softening point is much higher than that of regular bitumen. The penetration index (PI) is also higher (8 > PI > 2) compared to road construction bitumen, which has a gel-like structure due to asphalt accumulation. Blown Bitumen 75/25 is a semi-solid grade of pure petroleum bitumen. Its special physical properties make it suitable for various applications in the construction industry.

Blown Bitumen 75/25 is produced by the air-blowing of penetration grade bitumen at high temperatures, resulting in a material with a significantly higher penetration index. RAHA Bitumen 75/25 is made by blowing bitumen 60/70 with very hot air. The designation “75/25” refers to the midpoint of the softening point acceptance criteria.

RAHA Bitumen 75/25 is manufactured through either a Continuous or Staggered Blowing Process. Heated Penetration Grade Bitumen is blown with air under controlled conditions to manage the oil content while the bitumen oxidizes. The various grades produced for different applications are designated by two numbers indicating the midpoints of their softening point and penetration ranges.

10 PPM Diesel

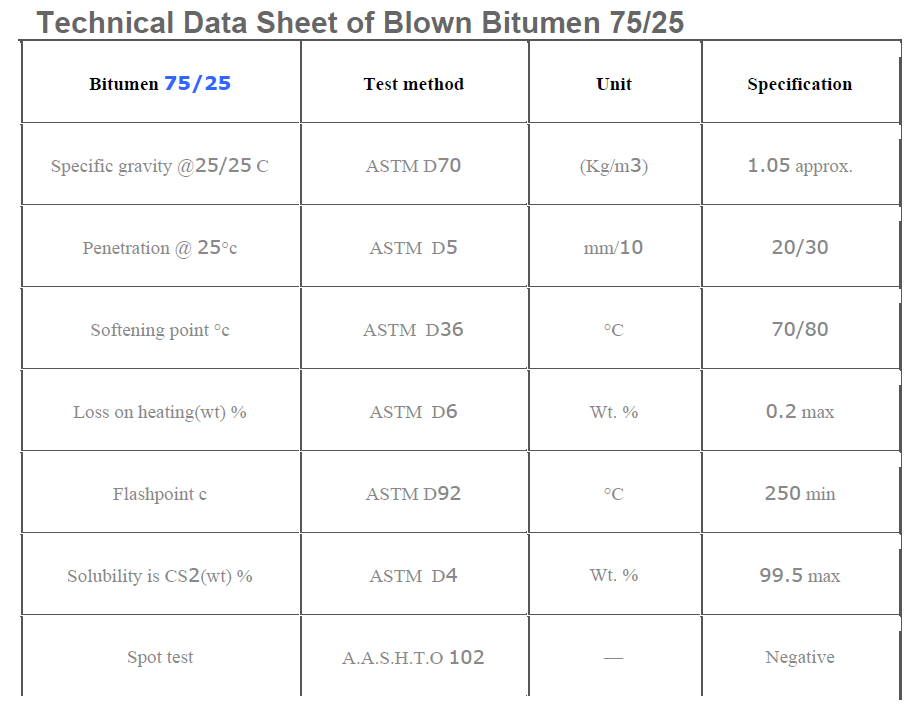

As previously mentioned, Blown Bitumen 75/25 is based on petroleum bitumen derived from the oxidation of 60/70 grade bitumen using very hot air. The numbers in its designation relate to the midpoint of the softening point and penetration, respectively. The softening point is measured by the Ring and Ball method (ASTM D36), while the penetration value (in 1/10 mm) is determined by IP49 or ASTM D5.

RAHA Bitumen Co. can also produce other grades of Oxidized Bitumen tailored to individual client specifications. Oxidized Bitumen is highly flexible, durable, completely water resistant, and chemically stable. These characteristics make it highly sought after in various industrial applications.

Uses of Blown Bitumen 75/25

Blown Bitumen 75/25 is a solid or semi-black solid material that becomes liquid when heated. Oxidized Bitumen grades are produced by passing air through soft bitumen at controlled temperatures. This process imparts rubbery characteristics, unlike penetration or hard grade bitumens, enabling diverse industrial applications.

These grades are suitable for sealing saw cuts and joints with minimal movement. Their broad temperature range prevents bleeding in high-temperature conditions. Industrial uses include pipe coating, roofing, waterproofing, flooring, mastics, sound damping, carpet backing, adhesives, and electrical applications. Hard bitumen under controlled temperature conditions is widely used in:

- Anti-slip layer compounds in piling

- Roofing felts manufacturing

- Roofing and waterproofing

- Sound dampening felts

- Under-carriage sealants in the automotive industry

- Electric cable joint protection

- Joint filling and sealing compounds

Technical Advantages of Blown Bitumen 75/25

- Durability

- Flexibility

- Water Resistance

- Chemical Stability

Compared to paving grade bitumen:

- Reduced temperature susceptibility

- More solid nature at ambient temperatures

- High penetration index

Recommendations for Handling / Storage

Heating packaged bitumen is a critical phase in most applications. Typically, it is melted in boilers on-site. Proper control during heating is essential for safety and product quality.

- Maximum safe handling temperature: 230°C (must not be exceeded)

- Bitumen is a poor heat conductor; hence, control of the heating phase is paramount

- Break the material into smaller pieces before placing it in the boiler to expose a larger surface area

- Avoid aggressive heating at the boiler base and sides to prevent localized overheating and thermal cracking

- Never reheat solidified bitumen in the boiler; this may cause a pressurized pocket of low flash vapors

- Place temperature monitoring devices carefully; readings away from the heat source may be inaccurate by several degrees

Health & Safety

Workers must wear protective masks, gloves, and goggles during application. Asphalt residues can be removed from tools with kerosene or gasoline. Overheating must be strictly avoided. For complete safety guidelines, refer to the Material Safety Data Sheet (MSDS).

Application of Blown Bitumen 75/25

RAHA Bitumen 75/25 is produced by either the Continuous or Staggered Blowing Process. Heated Penetration Grade Bitumen is oxidized by blowing air under controlled conditions, which regulates the oil content. Grades suited for different applications are denoted by two numbers, indicating the midpoints of softening point and penetration ranges.